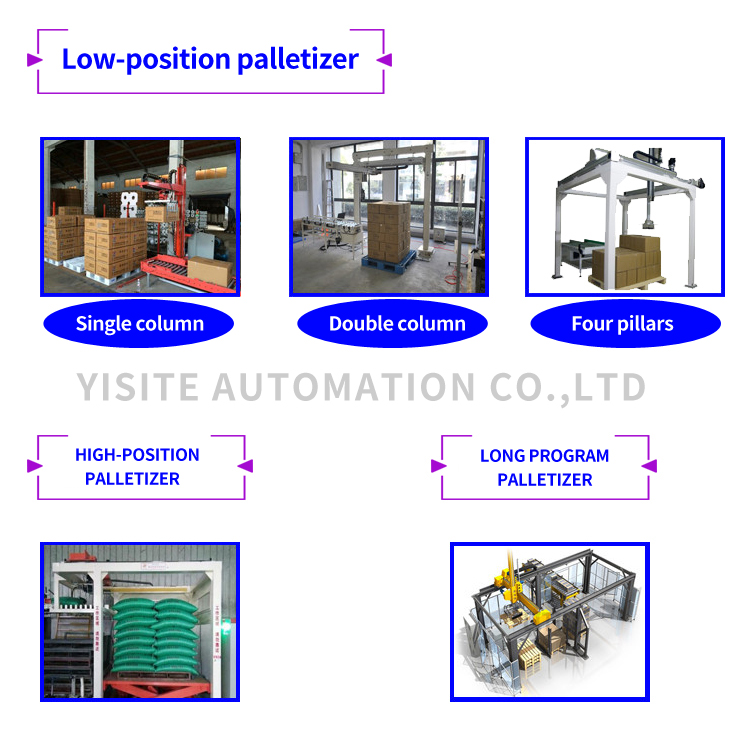

Products

masaga makatoni otomatiki gantry palletizer

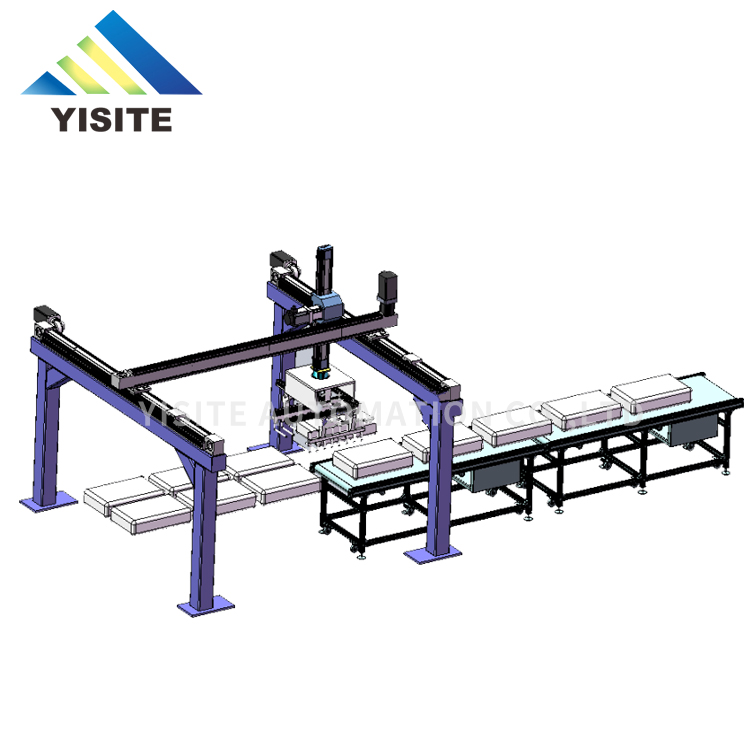

Kurongedza bhegi zvizere otomatiki truss inobata palletizing manipulator

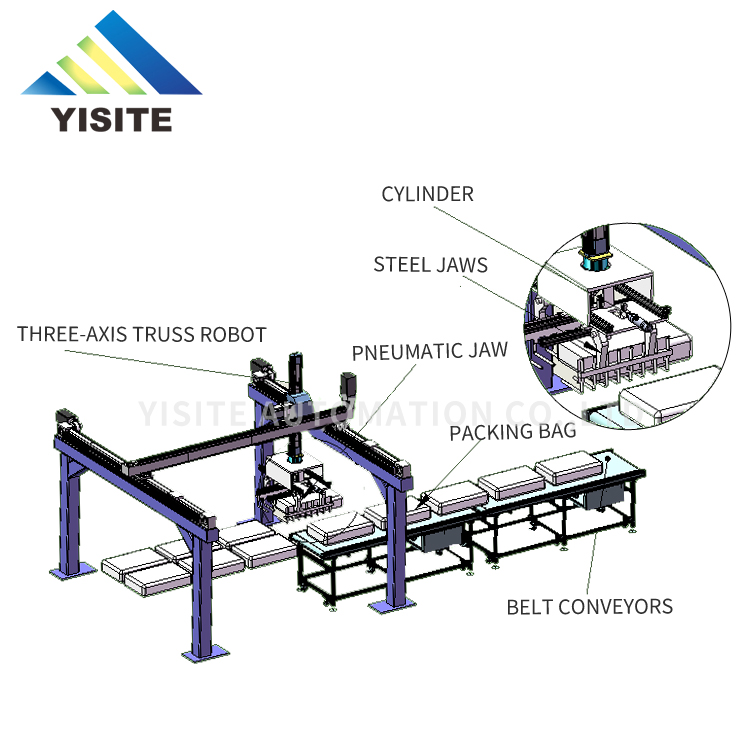

Otomatiki palletizing basa richaita zvakachena uye otomatiki kurongedza (kana dismantle) pane tireyi (kana yekugadzira mutsara, nezvimwewo) yechimiro chakasiyana uye saizi yekurongedza.Kuitira kushandisa zvizere nzvimbo yetireyi uye kugadzikana kwekurongedza zvinhu. , iro robhoti rine zvinhu zvakarongerwa kurongeka uye kurongeka kwekugadzirisa mudziyo.Inogona kusangana kubva pakumhanya kwakaderera kusvika pakumhanya kukuru, kubva pakurongedza bhegi kuenda kubhokisi, kubva papalletizing chigadzirwa kune zvakasiyana siyana zvigadzirwa.Inoshandiswa kune chigadzirwa kubata, palletizing uye nezvimwe. inoshandiswa muindasitiri yemakemikari, mapurasitiki, zvekuvakisa, mushonga, chikafu, zvinhu zvebhatiri uye mimwe minda yakasiyana.

ents, kushanda kwakagadzikana, kushanda kwakavimbika uye kusimba kwakasimba.

3. Zvivako zvekudzivirira zvinopiwa. Kana gonhi rekuvhara rakavhurwa, muchina unoshanda auto-mira.

4. Kugadziriswa kweiyo stacking mode iri nyore uye iri nyore, uye inogona kuitiswa pane yekubata skrini.

5. Nzira dzinoverengeka dzekututira dzinogona kupedzwa pasina kutsiva zvikamu zvekututira.

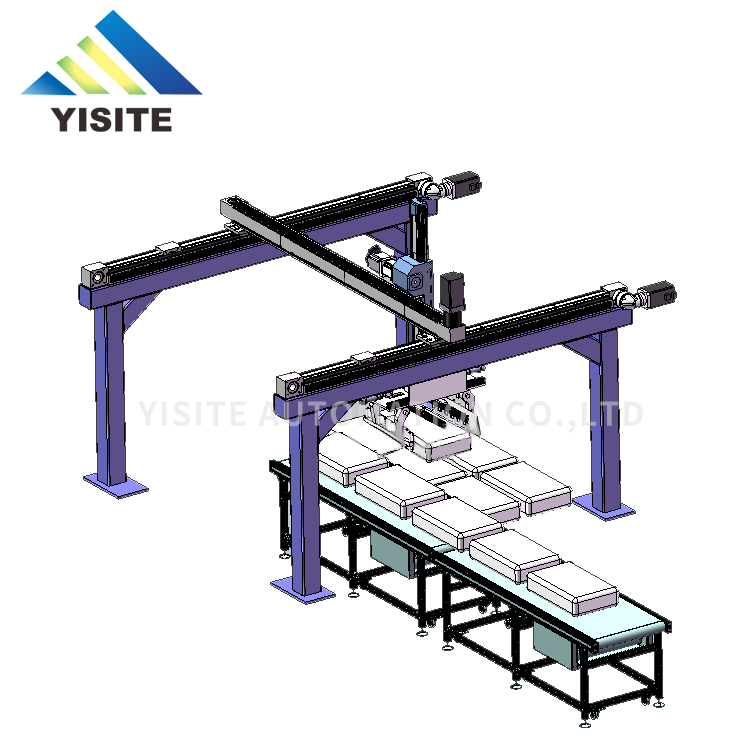

6. Inopindirana ne 2 trays, inonyanya kushanda uye inokurumidza

Zvakanakira zve otomatiki palletizing manipulator

1. Nyore uye inochinjika: bhegi kurongedza uye kubata palletizing robhoti inoumbwa nekufambisa mbozha uye bhegi kurongedza palletizing manipulator, palletizing robhoti ine zvakanakira nyore, inochinjika, diki simba, kuponesa simba, yakaderera mutengo uye nezvimwe zvakanakira;

2.Kuchengetedza basa nekuvandudza kushanda zvakanaka: robhoti inobata palletizing inogona kupedzisa kubata, kubata, kurongedza mabhegi uye zvigadzirwa zvekutakura, izvo zvinogona kuchengetedza zvakanyanya mari yebasa uye kuvandudza kushanda kwekushanda kwemabhizinesi;

3. Kurumidza kumhanyisa uye kurongedza kwakarongeka: bhegi otomatiki kurongedza kurongedza midziyo inogona kuita otomatiki stacking mashandiro emabhegi ekurongedza akasiyana, ane hunhu hwekukurumidza kurongedza kumhanya, kutsvinda kurongedza uye yakakwirira automation level;

4. Kukanganisa kwakaderera, nyore kuchengetedza nekugadzirisa: bhegi packaging automatic mechanical stacker structure iri nyore kwazvo, saka chiyero chekukundikana chakaderera, chiri nyore kuchengetedza nekugadzirisa.Zvishoma zvikamu zvikuru, zvishoma zvishandiso, mari yekuchengetedza yakaderera;

5. Kushanda kuri nyore uye kwakakodzera: bhegi rinotakura otomatiki stacker rinogona kuiswa munzvimbo yakamanikana, uye zvinobudirira kuendeswa kunzvimbo yakatarwa maererano negwara rakatarwa nemushandisi. Yese kutonga inogona kushandirwa pane control cabinet screen, uye kushanda kuri nyore;

6. Versatility basa: iyo paltizing uye stacking yezvinhu zvakasiyana zvinogona kupedzwa nekutsiva clam grab ye manipulator, kuitira kuti inoderedza mutengo;

7. Kushanda kwepamusoro-soro: zvakanakira kubata stacker manipulator inogona kushandiswa 24/7, inovandudza zvikuru kushanda kwekushanda uye hutano, kuzadzisa chinangwa chekuderedza kushandiswa uye kuwedzera kushanda;